Commitment to Made in Japan

We value the fact that our products are made in Japan as much as we value the use of genuine organic cotton.

Proud of Japan Made

"Less than 1% of domestic clothing is 'Made in Japan'"

Made in Japan is disappearing

The number of Japanese-made products is decreasing. When we talk to the engineers we work with, we feel that they have excellent skills and knowledge, and are always striving to improve. Not only in the textile industry, but all over Japan, businesses employing such engineers are being forced to close down every year.

We believe that the reliable and delicate technical skills that have been cultivated in Japan for many years are essential to ensure the safety of organic cotton. Therefore, we want to make the most of Japan's excellent technology, protect it, and pass it on to the future.

Cooperation between specialized regions and our own factories

Apparel products are made by dividing up the work into parts: fabric making, dyeing, cutting, sewing, inspection, and wrapping.

We do everything from sewing to inspection and wrapping in-house. For other parts that we cannot do in-house, we work closely with companies that we have had long-standing relationships with, consulting with them if there are any problems, and making improvements quickly and repeatedly, so that everyone involved continues to work sincerely on creating good products.

Making the dough

Fabrics are also produced in different places depending on the type. Pile fabrics are made in Imabari, Ehime Prefecture, which is famous for towels. No chemicals are used in the threads, which are softly twisted to weave pile fabric. Fabrics used for T-shirts and other items are made in Wakayama, where they are knitted in the same way as knitwear. Both methods eliminate as many chemicals as possible until the final process to maintain the texture and ultimate softness.

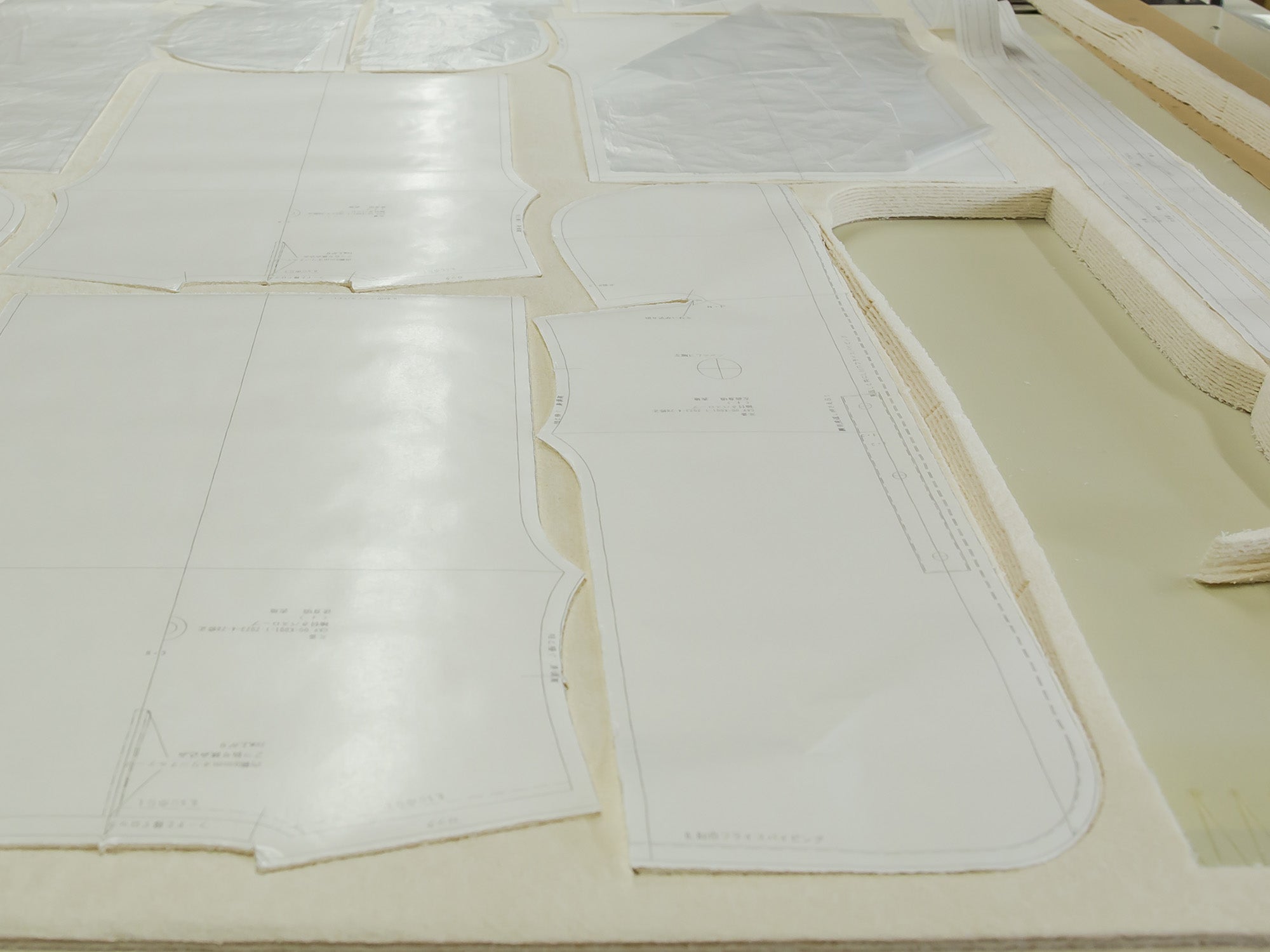

Cutting that supports manufacturing

The organic cotton fabric arrives in Wakayama. It is cut according to the pattern and with careful calculations to minimize fabric waste. This is delicate work, as even the slightest deviation in cutting can greatly affect the finished product.

High sewing precision

Sewing is done by skilled craftsmen with many years of experience. We communicate closely with designers about sewing methods, and even consider the finish and feel of the garment. Another strength of Japanese sewing is the power of high-performance, specialized sewing machines. To make Organically products easier to make, sewing machine craftsmen make special parts to support the precise work.

Made in Japan for your peace of mind

Our products are all produced domestically, from the yarn to the finished product, and we are able to keep an eye on the finished products, which is why we are able to create safe products.

The process of becoming a towel fabric

Our towels are made using certified organic yarn, and are environmentally friendly Imabari towels that are made by minimizing the use of chemicals from pile weaving to finishing, and even taking into consideration the wastewater load. Imabari towels are Japan's largest towel production area, with a history of over 110 years. They have attracted attention from around the world for their top quality, achieved through traditional and delicate manufacturing techniques and the latest technology. Among these, we are confident that our towel fabrics are the "highest quality towel fabrics" in Imabari, as we are particular about everything from the materials to the auxiliary substances used in the production process, and even the environmental load.

1) Raw materials

Made with certified organic yarn (100% organic cotton)

2) Yarn processing

The thread is refined using natural soap, soda ash, and starch paste, with consideration given to the environmental impact.

3) Weaving

The pile yarn, cotton yarn, and bottom warp thread are all made from certified organic yarn.

4) Fabric processing

The fabric is desizing using enzymes and then finished by washing slowly over a long period of time.